Meet the Solidus Stabilizer

Effectively address the largest source of revenue loss and greenhouse gas emissions in the oilfield.

The Solidus Stabilizer prevents tank vapors from forming by removing gas under pressure before storage. This decreases oil shrink and emissions and increases profit within a few hours of installation.

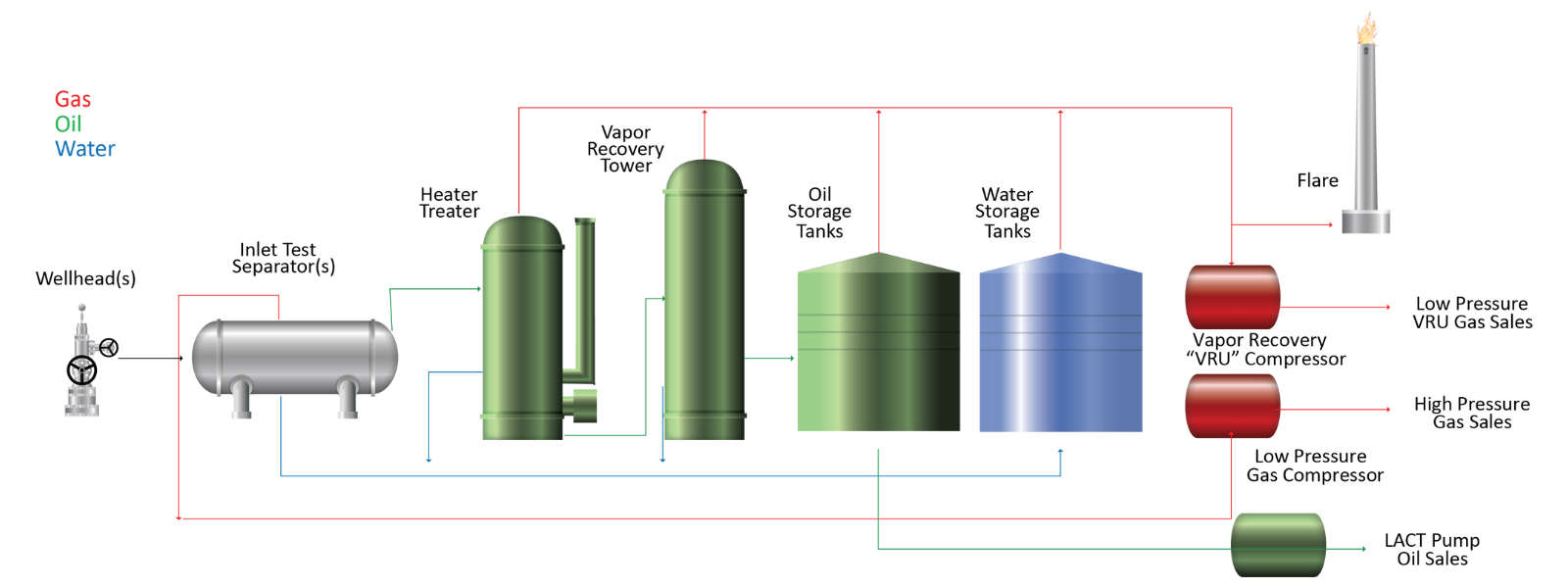

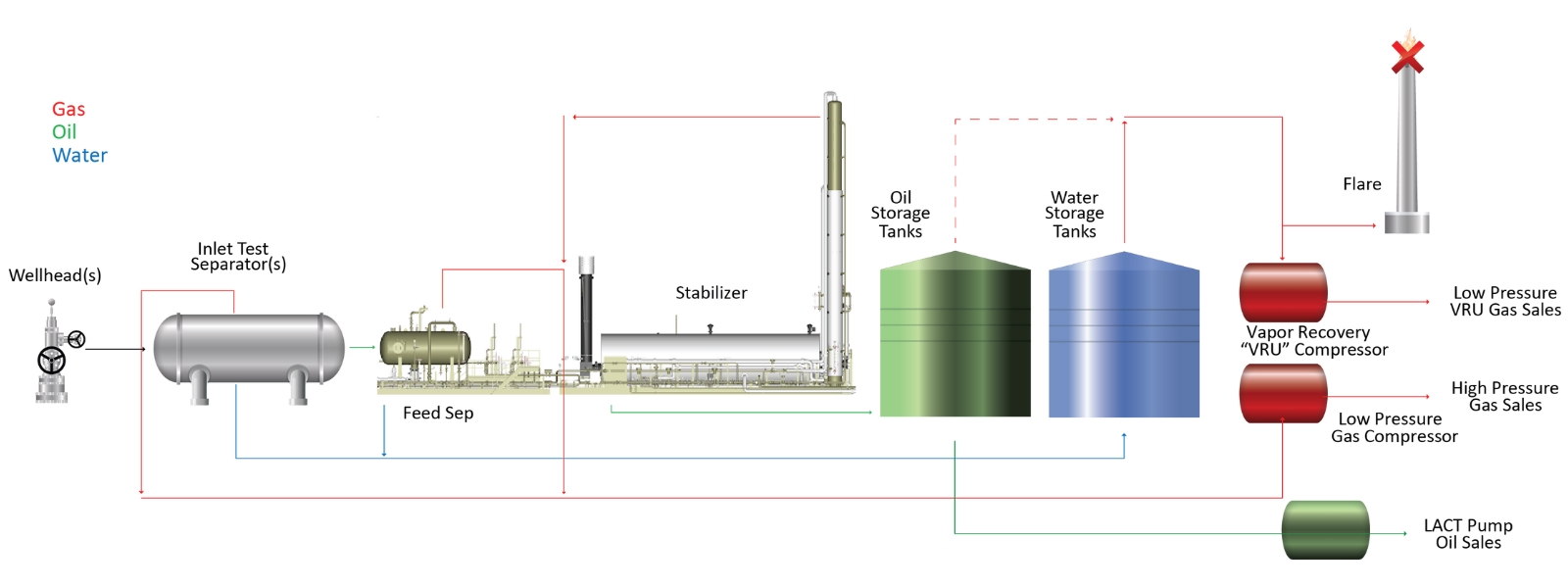

Your Current Facilities

Typical wellhead and central production facilities have limited separation stages, flashing off many NGLs in the heater treater and tanks. As a result, NGL-rich gas goes to flare or VRUs and is sold for a steep discount to oil price.

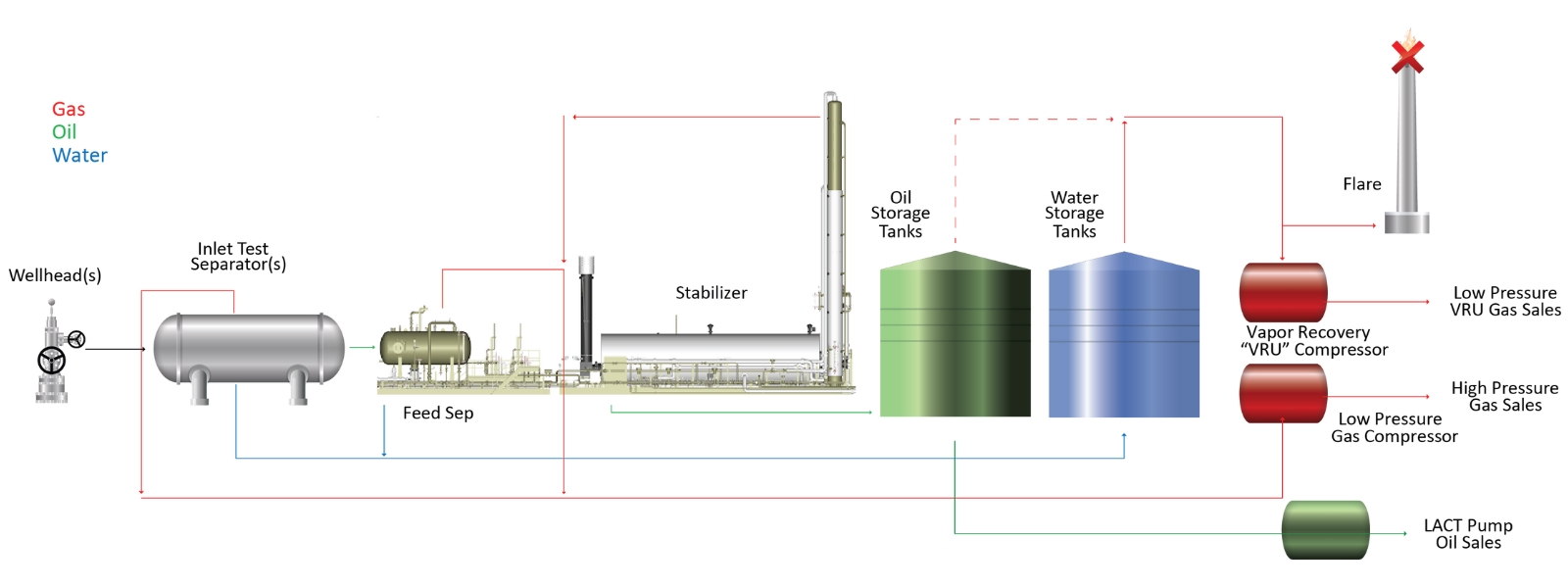

Facilities With Stabilization

By replacing heater treaters and VRTs with distillation-type stabilizers, we break up hydrocarbon chains and allow more NGLs to remain as stable dead oil. This increases oil sales volumes by up to 15% and reduces or eliminates flaring and tank VRUs.

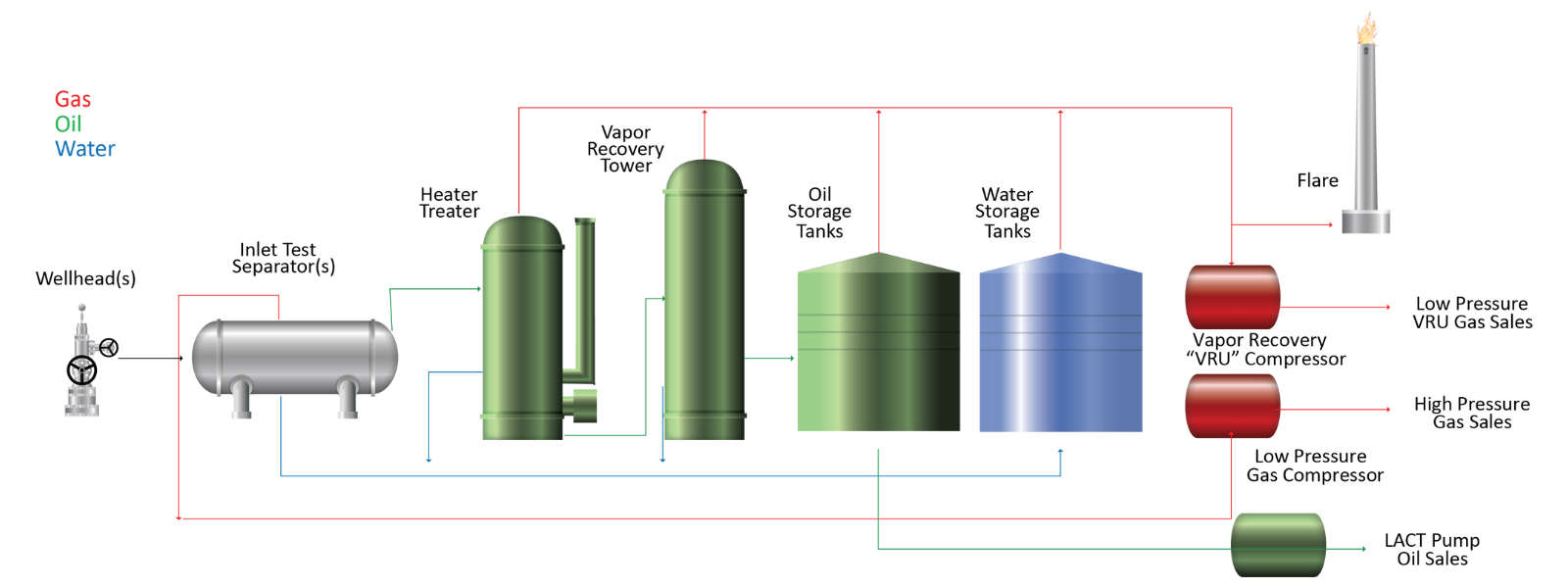

Your Current Facilities

Typical wellhead and central production facilities have limited separation stages, flashing off many NGLs in the heater treater and tanks. As a result, NGL-rich gas goes to flare or VRUs and is sold for a steep discount to oil price.

Facilities With Stabilization

By replacing heater treaters and VRTs with distillation-type stabilizers, we break up hydrocarbon chains and allow more NGLs to remain as stable dead oil. This increases oil sales volumes by up to 15% and reduces or eliminates flaring and tank VRUs.

STABILIZATION SERVICES - HOW WE WORK TOGETHER

Get Started

Solidus engineers work with your team to evaluate your current (or anticipated) oil composition and facility setup to determine possible liquids uplift and emission reductions or to confirm that you are currently set up for maximum efficiency, free of charge.

After developing an understanding of the process conditions, Solidus will propose a fit-for-purpose, low or no capex stabilization solution that improves your cash flow and reduces field level emissions for a per barrel fee that declines with production and is typically less than additional oil economics.

Solidus and its partner, Tejas, will fabricate, install, startup, commission, maintain and optimally operate units for changing conditions to maximize liquids recovery and minimize methane and CO2 emissions.

Throughout the process we baseline existing or anticipated shrink and emissions, then work with third-party auditors to certify emissions reductions to help you meet ESG commitments OR possibly to further monetize stabilization by selling carbon offset credits!